This is Part Two of our little project - if you want to go back and check on something we did earlier, then click HERE.

Smitty

and I met again on Saturday, March 29th. This is the fourth

Saturday since we started working on this project and today

we're going to work on making the tail stock and try to figure

out how best to apply the grape vines and leaves to the central

logo.

My

original plan was to purchase a tail stock but the price tag

was severe enough to convince me to build one. Well, all that

and the fact that if I couldn't then someone oughta take my

birthday away.

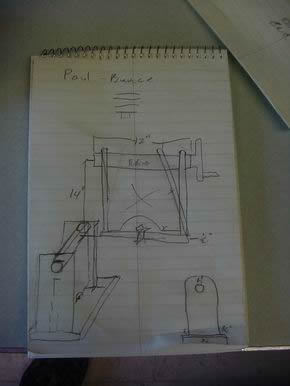

As

is my custom, we began with a plan. Here's our thumbnail sketch...

After

we discussed the sketch Smitty turned to look his 'puter in

the face and drew the components making up the tail stock then

sent them to the CNC plasma cutter.

While

he was cutting the tail stock parts, I was busy creating the

vines. They're made from 1/4" round stock that were sanded

with random flat spots. I made the odd bends by inserting the

rods into various sized holes that were drilled into the surfaces

of Felco's steel work tables. Here you see the first

of the vines sitting in position.

Each

section making up the vines are bent differently to give the

illusion of being real vines. Although each one took approximately

30 minutes to bend, cut and fit in place I did find a few moments

to sneak away and imagine my surprise when I actually caught

Smitty working! Here, he's fixing to grind one of the tail stock

pieces.

Meanwhile,

back at the vineyards the vines have reached maturity. Smitty

caught me goofing off trying to figure out how to bend the leaves

so they'll look natural.

Then

it hit me, "Hey, Dummy! They'll look perfectly natural

if you bend them naturally!" So, I toddled off to a vice

and clamped each leaf between the jaws and smacked it with a

single jack, then rotated the leaf and smacked it again. This

process was repeated until each blank looked like a leaf.

Nature

doesn't have the market cornered on making leaves - here's what

one of mine looks like. The veins still need to be ground but

all that business will happen after they've been applied.

Once

I had them all looking like leaves each one was clamped in place

then the logo was turned over so they could be welded from behind.

The welds holding the vines to the perimeter are only temporary

and will be ground off later.

And,

here is what Smitty has been working on - it's the opening kickoff

of what the tail stock will look like. The arch at the bottom

allows access to the bolt that clamps the tail stock to the

ways.

Believe

it or not, in-between breaks we found plenty of time to complete

the vine motif!

A view of the lathe with the stuff we did today - sorry for the

poor picture, I'll retake when we reconvene - she's getting

heavier!

Move on to Part 3 if you want to see more. |