|

Don't get me wrong, I like Norm

Abram. I think he has a ton of talent and does a bang up job

instructing and propagating woodworking but I have to say it pains

me severely to watch him build regular, run-of-the-mill, everyday

cabinets. He spends so much time and wasted energy on them

that I want to run screaming into the night. We're talking

basic kitchen and bathroom variety cabinets here, not ship-going

vessels. The function of a cabinet is to sit there or hang

there and that's it, that's all it'll ever do. All those fancy

screws and all the glue and all them rabbets and dadoes he uses are

totally unnecessary. There, I said it and I'm not the least

bit afraid of doing so.

I've been stapling cabinets

together for twenty years or better and I have yet to hear of one

falling apart or coming off a wall. So, before I go any

further let me address how I go about making my cabinets:

-

I use quality sheet

goods; AC or BC plywood, Melamine or particle board (more on this later)

-

I have a dimensioned drawing of

all my cabinet sizes - both base and wall (this makes my material

cutting faster and easier)

-

The only thing I fret on are the

face frames - in other words I don't get anal on carcase assembly

That's it! Those are the only

things so let's move on.

Tools you'll need:

-

A tablesaw - yes,

you could cut the parts with a circular saw but a TS is faster and

more accurate

-

A 1/4" crown stapler

capable of shooting 1 1/2" and 1 1/4" staples

-

A brad nailer capable of

shooting 1 1/2" brads

-

An air compressor

-

A planer

-

A drywall square

-

A framing square

-

A miter saw

-

A hammer

-

A pair of dykes

-

A pencil

-

A pencil sharpener

-

Lighting

-

Electricity

-

A workbench

-

Pipe or bar clamps

-

A cordless drill equipped with

a #2 Phillips or square drive bit

-

A stupid worthless cat

I'm pretty sure you can do without the damned

ole stupid worthless cat but the other stuff you'll need.

There are two types of cabinets; base and

wall. Any that rest on the floor are base cabinets. Guess which ones

are on the wall?

If you said 'wall' then you're an excellent

guesser.

Ok, the next thing are the cabinet rules.

These rules are for standard base and wall cabinets, meaning 24" deep x 34 1/2"

high and 12" deep x 30" high respectively (if you want your cabinets different

then you'll need to adjust these dimensions accordingly). These rules

shall never change so consider them chiseled in stone.

I know, you're saying, "But Dear ole Joe, base

cabinets are 36" high how's come yours are 34 1/2" high?" Well, that's

because we haven't put on the counter top yet. Don't worry, we'll get

there.

Base cabinets

-

Sides and partitions - 22 3/4" x 29"

-

Bottoms - 22 3/4" x however wide the face

frame is minus 3/4"

-

Shelves - 14 3/4" x however long they need to

be - you don't want the shelf the full depth

-

Backs - however long the bottom is x 29 3/4" x

1/2" thick (this is the only 1/2" material used on the base cabinet)

-

Toe-kick - 4 3/4" wide strips and 2" wide

strips (I get these out of the scrap so cut them last)

Wall cabinets

-

Sides and partitions - 10 3/4" x 26 7/8"

-

Shelves - 10 3/4" x however long they need to

be - on wall cabinets you want them the full depth

-

Bottoms and tops - however wide the face frame

is minus 3/4" x 10 3/4"

-

Backs - however wide the face frame is minus

3/4" x 28 3/8" x 1/2" thick (this is the only 1/2" material used on the wall

cabinet)

Face Frames

-

All rails are 2" wide (using

pocket hole joinery is best however butt joints work well)

-

All outside stiles are 1 5/8" wide*

-

All partition stiles are 1 3/4"*

-

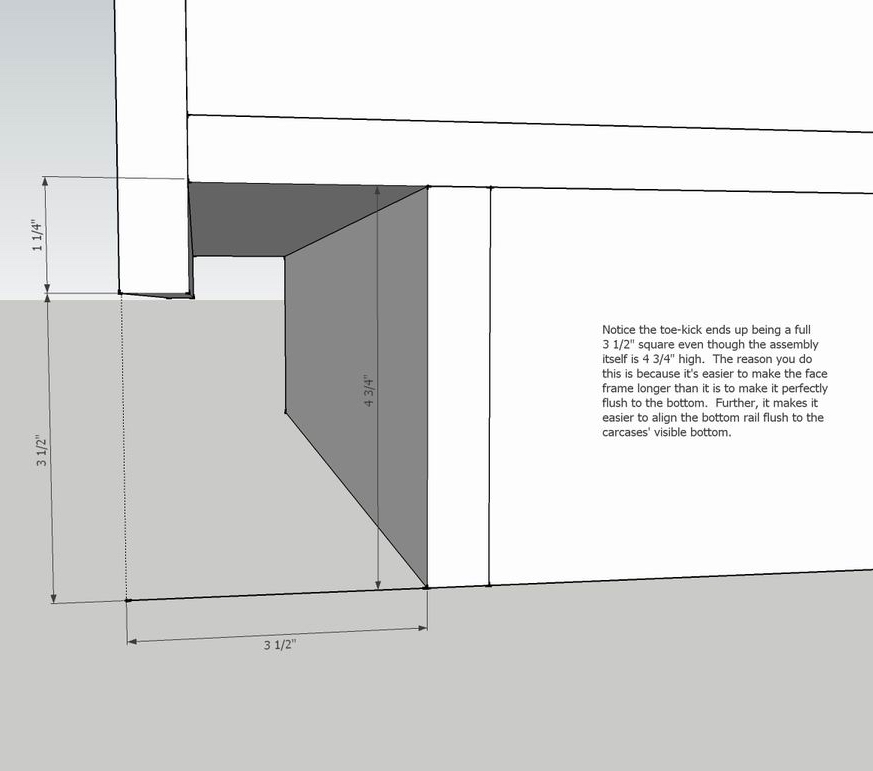

Face frames extend 1 1/4" below the carcase

(see drawings below)

* - These widths allow you to use

1/2" spacers when/if it comes time to install drawers (see the

drawer video links at the bottom of this course).

The intended use of a cabinet determines what sheet material will be the components

making up the cabinet; if it's a cabinet in my shop then the carcase will be plain

particle board. If I'm making a set of kitchen cabinets then they are always Melamine;

it's already finished, easy to clean and looks professional. Plus, it comes in different

solid colors and patterns - nice stuff. One caveat though...be careful handling it

after making a cut - the edges are very sharp and will slice you damn near to the bone.

I try to avoid using plywood unless the grade is AC or better and even with that I

have issues; voids between the layers, football shaped fillers that are all too

visible when a finish is applied, the thicknesses being odd-sized and the cost. Basically,

unless I'm trying to match cabinets already in place or the client specifically

requests it, I don't use plywood.

The first thing I do is cut all the components

making up the cabinets and mill the face frame material. I stack them

against a wall in sections; tops/bottoms, sides/partitions, backs, etc. I

do this because I place trust in the cut list generated from a 3D modeling

program called SketchUp and you'd do well to

download this wonderful program. With it in hand I can easily cut all the parts

for an entire set of average kitchen cabinets in two hours and never once question

the accuracy of the dimensions.

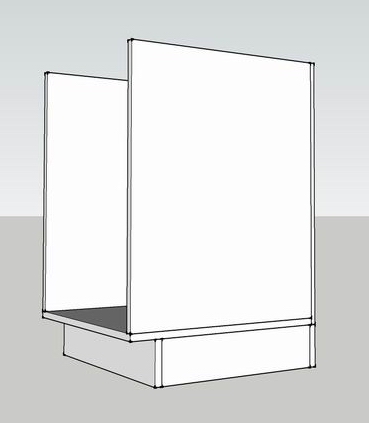

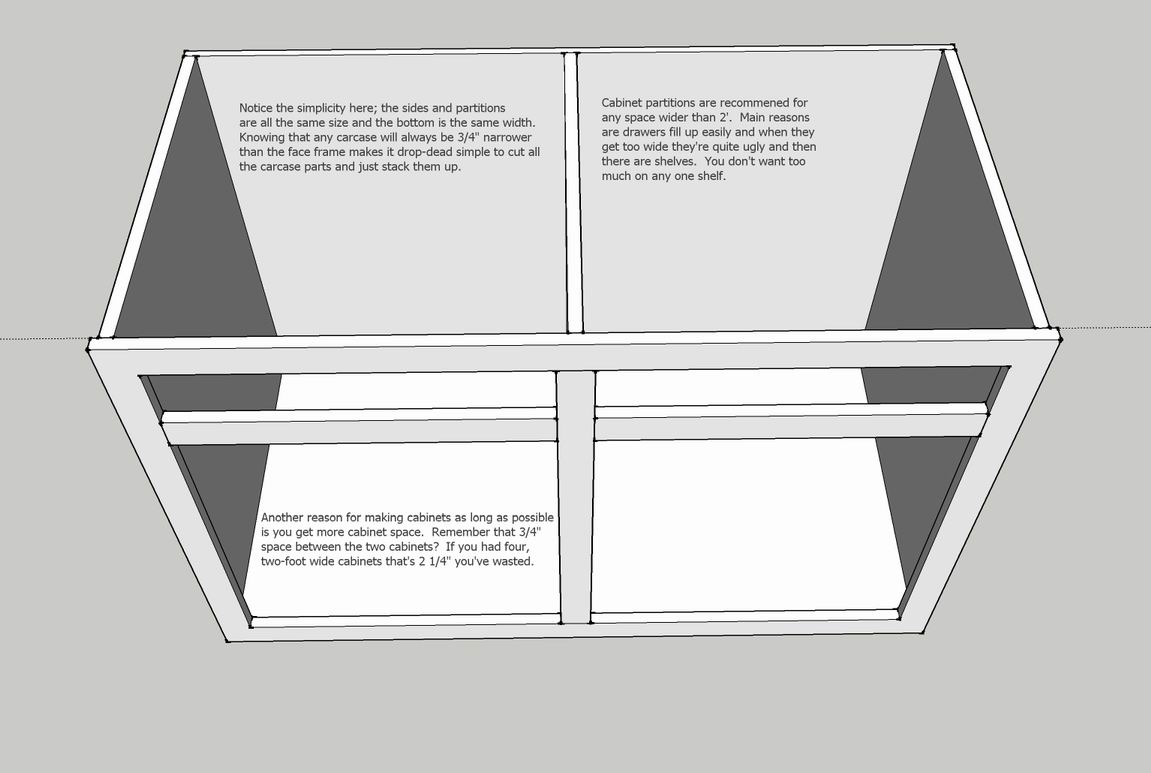

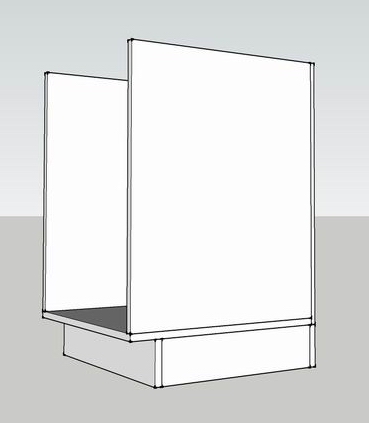

Take a look at this model of expanded parts making up a

standard base cabinet. Notice there are only four major parts; the

back, the sides and/or partitions, the bottom and, finally, the toe-kick

assembly.

And this is what is looks like assembled.

Assembling the basic carcase couldn't be simpler.

Stand the bottom up on your floor and lift one of the sides or partitions into

place, staple it every 3" using 1 1/2" staples then repeat for the remaining

side and/or partitions. Now you have at least a "U" shaped figure.

Place the back on and begin stapling (without changing sizes - this is all about

speed here) it onto the carcase frame making sure one side and the bottom align

then staple the other side. If your cuts are square then your carcase is

square. In other words, don't worry about it, move on.

After all the base cabinet carcases are assembled

and laying scattered on your shop floor, it's time to put on the

toe-kick-assembly. Run around and stand all the carcases bottom up and use

the scrap material left over to cut the pieces. Staple them as shown

below.

The toe-kick couldn't be simpler. See

how the assembly raises the carcase off the floor? See how the face frame

extends below the carcase bottom? An 1 1/4" + 3/4" is 2"! Presto!

With the rails milled to 2" all you have to do is flush the face

frame with the upper surface of the bottom shelf while making sure to overhang

the stiles by

3/8" on each side. |